The parameters that need to be measured on a fracturing job include, pump rate, pump total, pressure, and sometimes fracturing fluid density.

Usually in the case of fracturing pumps pump stoke counter due to the large size of the plunger rod and the lack of a convenient rotating flange on the drive shaft the stroke counter is installed near one of the plungers on the pump. In this case the stroke counter senses the back and forth motion of a collar on the plunger and generates a pulse for each cycle of the pump.

For fracturing it is important to know both the pumping rate and the total volume pumped by a pumping unit. If more than one pump unit is being used then the total volume pumped by all of the units combined together needs to be known. In order to do this the data acquisition system needs to record the frequency of the pump stroke signal pulses and also keep track of the total number of signal pulses. The displacement of the pump and the total number of plungers needs to be known in order to be able to determine the pump rate and total volume pumped.

This method of pump stroke measurement applies to all types of pumps where a rotary shaft has been instrumented for pump rate measurement.

The measurement of pump pressure on fracturing pumps is done in one of two ways. In some cases each fracturing pump is equipped with a pressure sensor and in other cases there is a single pressure sensor is installed on a Tee in the treating iron near the well head. This sensors monitors the combined fracturing pressure for the fracturing job.

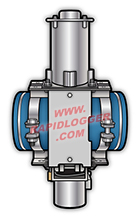

The proppant used in the fracturing fluids is extremely abrasive and erodes the walls of the pipe that it is flowing through. It also damages any sensors installed in the pipe. For this reason the measurement of fracturing fluid density or proppant concentration for a fracturing job is almost always done by means of a non contacting densitometer. A radioactive densitometer is one such device that works best. The Rapidlogger data acquisition has a built in mode for efficiently setting up and recording oilfield fracturing jobs.