Rapidlogger Systems designs and manufactures rugged and efficient monitoring systems for drilling, pumping, and well intervention services. Our systems are extremely rugged and designed specifically for the harsh oilfield environments.

Highlights

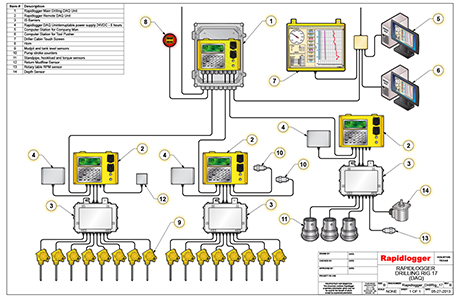

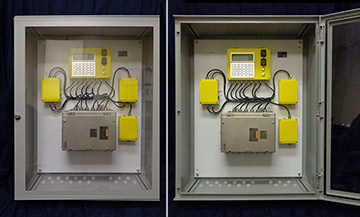

Each Rapidlogger unit is a compact standalone and cost-effective system for oilfield data acquisition and control. A single unit can be used for pump monitoring, cementing, mud, coiled tubing and slickline units. Additionally multiple Rapidlogger systems can be connected together over a digital bus for creating complex rig control solutions.

Each Rapidlogger unit can record sensor data on internal memory. Each unit is equipped with serial, Ethernet and USB connections to facilitate connectivity.

Mud Pump Mode

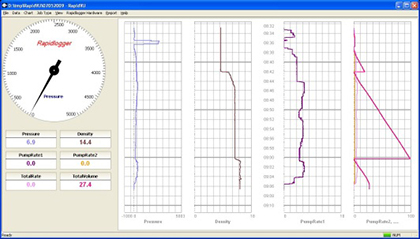

When used in the Mud pump mode the system measures, displays and records, the pump pressure, rate, and volume. The data is also displayed on the unit.

Pit Monitor Mode

When used in the pit monitoring mode the system measures the pit level, calculates inflow, outflow, pit volume for up to 12 pits per unit. The data is also displayed on the unit.

Rig Floor Monitor Mode

When used in the rig floor mode the system measures the standpipe pressures, Rotary RPM, Rotary Torque, Depth, and Hook load. All of this data is visible on the local display and is transmitted to the main unit.

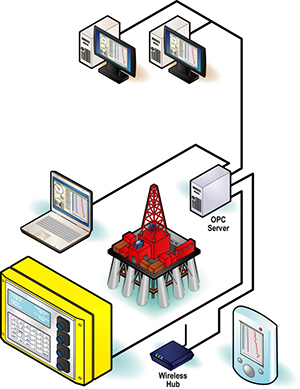

Software Interfaces

In order for the system to be truly universal and compatible, the Rapidlogger system allows data input and output via OPC, WITS, Modbus and ASCII streams. These are available over Ethernet. WiFi and serial links.

The RapidVu is the software for graphing and preparing quick reports on a PC. The RapidVu program is not required to run and record a job but if needed can acquire data from the Rapidlogger system in real time or play back a previously recorded job from a USB stick.

Specifications

| Operating Temperature: | -40C to 70C |

| Operating Enviornment: | NEMA 4X |

| Analog Inputs: | 12/48 max, 16bit |

| Frequency Inputs: | 4 / 16 max |

| Digital Outputs: | 2 / 8 max |

| Display: | LCD w/ Backlight |

| Computer Interface: | Serial, Ethernet, USB |

| Power: | 12/24DC,110/240AC |

| Job Memory: | 1GB |

| MTBF: | 200,000 hours |