Oilfield Job Monitoring Software from Rapidlogger Systems

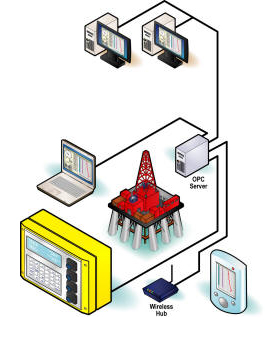

Rapidlogger Systems is a provider of efficient monitoring software and hardware systems for oilfield applications. The RapidVU is a software application for the PC. The program can be used to connect directly to the Rapidlogger hardware over Ethernet cable, WiFi and Serial Channels. They can also connect to hardware from other providers and display and record job data over these channels. Additionally they can connect to Rapidlogger and third party OPC servers to acquire data.

RapidVu Software protocols and capabilities include: OPC, MODBUS, WITS, ASCII, CAN, and Excel. The protocols options for OPC, Modbus and WITS can be used for exchanging Rapidlogger device data with the Rig computers and PLCs. They were developed with communication flexibility in mind. The data interface also allows communication via ASCII stream type protocols and CAN interfaces, additionally export of data to excel is also supported.

The Rapidlogger OPC Data Gateway allows for multiple clients to be able to send and receive data to a single OPC server via ASCII protocols. The Rapid VU is the optional laptop software for generating job reports and downloading data to the PC runs under Windows (XP/Win7). The laptop and the PC software is not needed for operation or job recording. It is only required for generating job reports from Rapidlogger system.

Rapidlogger software can operate in a few different modes.

Coiled Tubing Mode:

In this mode the system measures, displays and records: depth, speed, weight, wellhead pressure, circulating pressure, and other parameters.

Slickline Mode:

In this mode the system measures, displays and records: depth, line tension, wellhead pressure, etc. The system can also correct the depth for line stretch and thermal expansion.

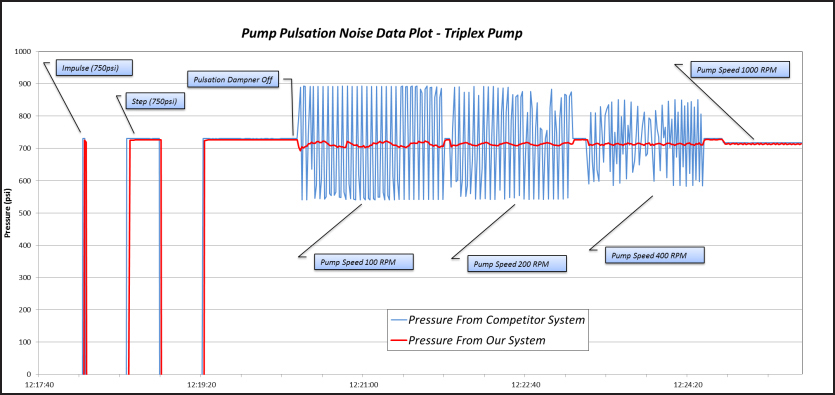

Pump Truck Mode:

In this mode, on a cementing, fracturing or acid pump, the system measures, displays and records: pump pressure, pump rate, inlet pressure etc.