Calibrating Pump Total and Rate Variables

This tech note describes the process to adjust the pump volume and pump rate variable on the Rapidlogger System.

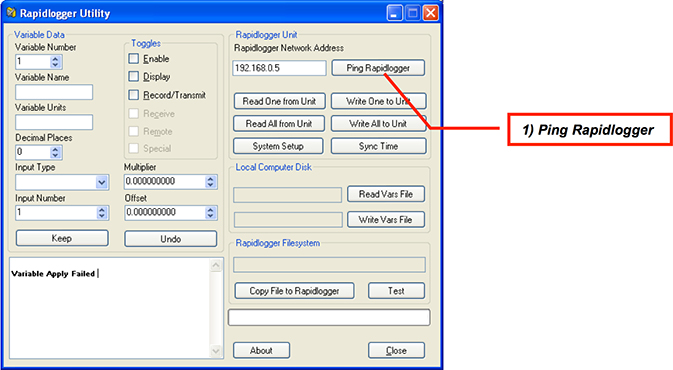

- The first step is to ensure that you have the Rapidlogger Utility program installed and working correctly on a laptop. Please make sure that the program is communicating properly with the Rapidlogger system before proceeding to the step 3.

- Ping the Rapidlogger from the Utility program by clicking on the “Ping Rapidlogger” Button

- Once communication has been verified. Click on “Read All from Unit”. This allows all Variable setups to be imported from the Rapidlogger. At this time it would be a good idea to save this Variable file to your computer using the “Write Vars File” button. This will allow you to recover the data if it is accidently corrupted or erased in the calibration process.

- Now click the up arrow on the “Variable Number” field to reach the proper variable for the pump total value. This is usually Variable 8 on a standard Cementing pumping setup. The variable will be called “Pump1Total”.

- Change the value in the “Multiplier” field to 0.000215. And press the “Write One to Unit” button. If the field was already stating this value then do not change it.

- Restart the Rapilogger system by powering it down and back up.

- Setup your pump test to Pump a known amount of water through the pump. For a cementing pump 10 barrels is a good value to pump.

- Once the pump is primed and a few gallons have been pumped. Stop the pump.

- Top up the fluid tank to be exactly 10 barrels (or the known volume of water that you intend to run this test with).

- Power cycle the Rapidlogger hardware so that the Pump1Total reads 0.0 barrels again.

- Start pumping at a steady rate until all of the fluid has been pumped through. Stop the pump immediately when the known volume has been pumped through. If you let the pump run dry for a few cycles after the fluid tank has been emptied then the calibration will not be as accurate.

- Record the actual value shown on the Pump1Total variable on the Rapidlogger Screen or laptop computer and also the volume of the fluid pumped.

- Enter the 0riginal Multiplier, Displayed volume, and Actual pumped volume in the accompanying spreadsheet (if no spreadsheet is attached to this document then please request a copy of the spreadsheet from support@rapidlogger.com). Make sure that only these three values are entered in the appropriate fields and no formulas are modified.

- The spreadsheet displays the corrected Multipliers for Pump1Total and Pump1Rate in the Red colored fields.

- Enter the new multiplier for Pump1Total in the Rapidlogger Utility “Multiplier” field for variable Pump1Total.

- Press “Write one to Unit” button. Wait for the write to properly complete.

- Now locate the variable for “Pump1Rate” and enter the New Pump Rate Multiplier from the spreadsheet in the multiplier field.

- Press “Write one to Unit” button. Wait for the write to properly complete.

- Power cycle the Rapidlogger hardware.

- The calibration of the Pump1Total and Pump1Rate Variables is complete.

- In order to verify you can run the calibration test one more time and see that the value of the fluid pumped accurately matches the value displayed on the Rapidlogger.

- If the pump being used is a double pump then this same procedure can be repeated for calibrating Pump2Total and Pump2Rate variables also.